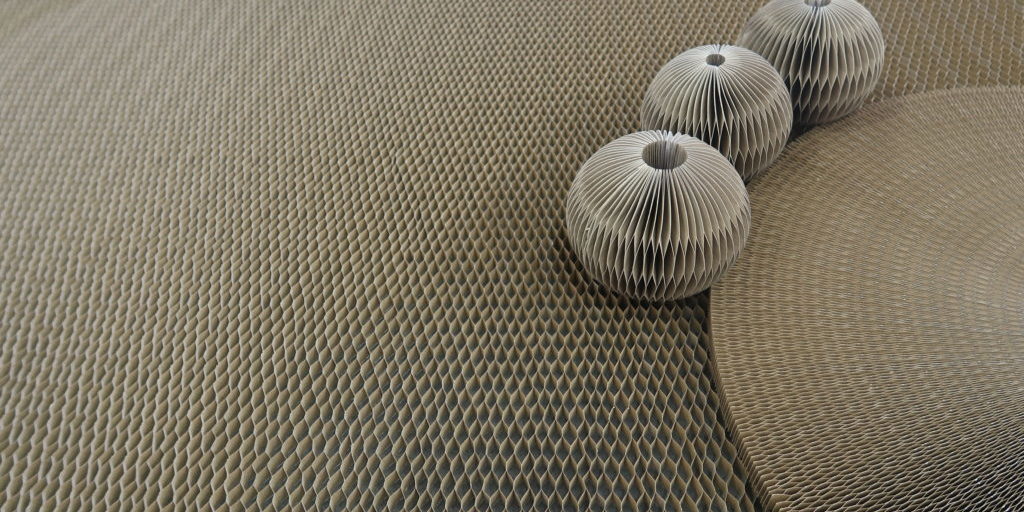

What is paper honeycomb core?

For many years, Bestem has been intensely focused on the subject of products made from honeycomb, and this term very often appears in the materials published by us. But what exactly is the honeycomb? What makes this product stand out from the others available on the market?

The history of this extraordinary structure dates back to the beginning of the 20th century, specifically to 1901, when Hans Heilbrun began the process of producing a paper honeycomb core at the Heilbrun & Pinner factory in Halle. In the 1950s, the shortage of materials such as brick or wood introduced this unique material to the US aviation industry. However, this is not the end of the exciting path of the so-called honeycomb core. Currently, the paper core is used in construction, automotive industry, but also in less conventional fields – in the production of advertising stands, paper furniture, security and packaging for a wide range of products.

Why to choose such an unusual shape of the cell itself?

It turns out that this idea was taken from natural cellular structures occurring, among others in rocks, human bones, plant stems or in the honeycomb produced by bees. For many years, mathematicians have suspected that when it comes to the best use of space and the smallest material consumption, the division into hexagons exceeds any other. Based on the experience of the best architects of the world – bees – scientists have created an extremely light, durable and biodegradable structure, which possible application still does not cease to amaze us.

How is paper core created?

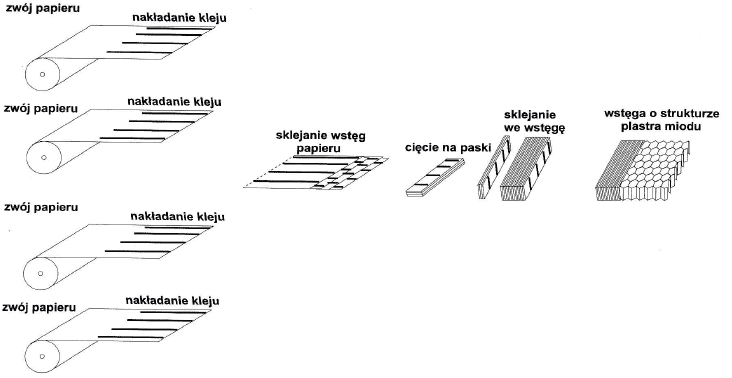

Two primary technologies can be distinguished here: a sheet and a continuous ribbon method. The sheet method is the oldest technology used in the field, but nowadays it has been largely supplanted by a more efficient continuous ribbon method (1), which allows for more significant savings in used materials, less use of glue and greater width of the filling web.

The continuous ribbon method in which the Bestem company specializes is a production process consisting, in short, of gluing paper webs which, after further cutting (up to the size corresponding to the core height) and re-gluing into blocks, form a continuous ribbon honeycomb.

(1)Scheme of production of the honeycomb core in continuous ribbon technology. [Kmita-Fudalej, G., Szewczyk, W.: Cardboard honeycomb products. Vol. I. Application and production, Paper review (2015)].

Additional factors differentiating the core are raw materials used for its production and geometrical parameters of the product. On the market, you can find a paper honeycomb core produced using papers of various weights, of multiple cell sizes (diameter of the circle inscribed into the cell) and cell heights. Bestem in its primary offer has four cell sizes: 8, 10, 14 and 22 mm and core height in the range of 7.5 – 103.5 mm, which allow for an excellent selection of material for the diverse needs of customers. The finished product is characterized by many advantages such as:

- low weight,

- high strength and stiffness,

- good acoustic, thermal and insulating properties,

- and most importantly it is fully biodegradable, does not pollute the natural environment.

For which products does Bestem use honeycomb?

Returning, however, to the possible use of the honeycomb – apart from the paper core itself, Bestem offers a wide range of products made of the honeycomb core. These are among others:

- Honeycomb paper pallets, which are characterized by significantly lower weight compared to wooden pallets and have been successfully pushing wooden or plastic pallets from the market for several years.

- Honeycomb boards used in many industries, such as transport, construction, automotive and aviation industry; but also in marketing in the production of advertising stands or exhibition furniture.

- Product protectors – excellent for securing goods during transport and storage. They cause stiffening and protect the transported product against its mechanical damage. They are light, stiff, durable and resistant to compression.

- Honeycomb packaging, which thanks to a large possibility of matching the shape of the fillings to the protected product, are characterized by high durability and unusual cushioning properties.

- Paper houses made of honeycomb panels – a creative toy for self-assembly designed for the youngest recipients. The ability to independently assemble and decorate the playhouse develops the imagination and manual skills of the child.

- Advertising stands and displays – a new form of advertising, prepared on a plotter, which, due to its ecological and innovative appearance, will allow you to stand out from similar projects.

These products are just a small fraction of the possible use of a honeycomb core. Its unique structure and extraordinary properties, as well as the growing awareness of the environment on the issue of ecology, attracts an increasing number of recipients, and its use will undoubtedly surprise us many more times.

(Author: Dagmara Śmierzchalska, Promotion and Marketing Specialist)