What it is and what is the best use of it?

For centuries, nature has proved to humanity that the solutions it creates are ideally suited to adaptation in many fields of science, industry or ultimately in our home environment. Many times researchers and designers proudly admitted that the results of their work were inspired by observations of the flora and fauna around us. These observations were also used at the creation of the first structures based on a cubic cell. The honeycomb created by the bees became a direct inspiration in this case, and what’s interesting, regardless of what material will be used at the production stage, attention is often drawn to the words “honeycomb structure”, which in their own way honor the true inventor.

A unique structure, infinite possibilities.

The hexagonal architecture of the material can give the products created in this technology a lot of unique properties. Low weight combined with exceptional resistance to compression or the possibility of stiffening the structure while maintaining minimal flexibility, motivates more and more industries to a wider implementation of the discussed solution. We therefore meet products using a honeycomb structure made of aluminum, carbon fiber, plastic, kevlar or paper. In addition, many of these applications bring tangible results, and therefore contribute strongly to the development of our civilization. Particular attention should be paid to paper boards based on the construction of a cubic core. They are used, among others, in the packaging industry, and despite their relatively simple construction, they perfectly match the needs resulting from the growing public awareness of ecological issues. As a consequence, these boards are increasingly becoming a substitute for foams and plastics which harm our health and pollute the natural environment.

How is a honeycomb board built?

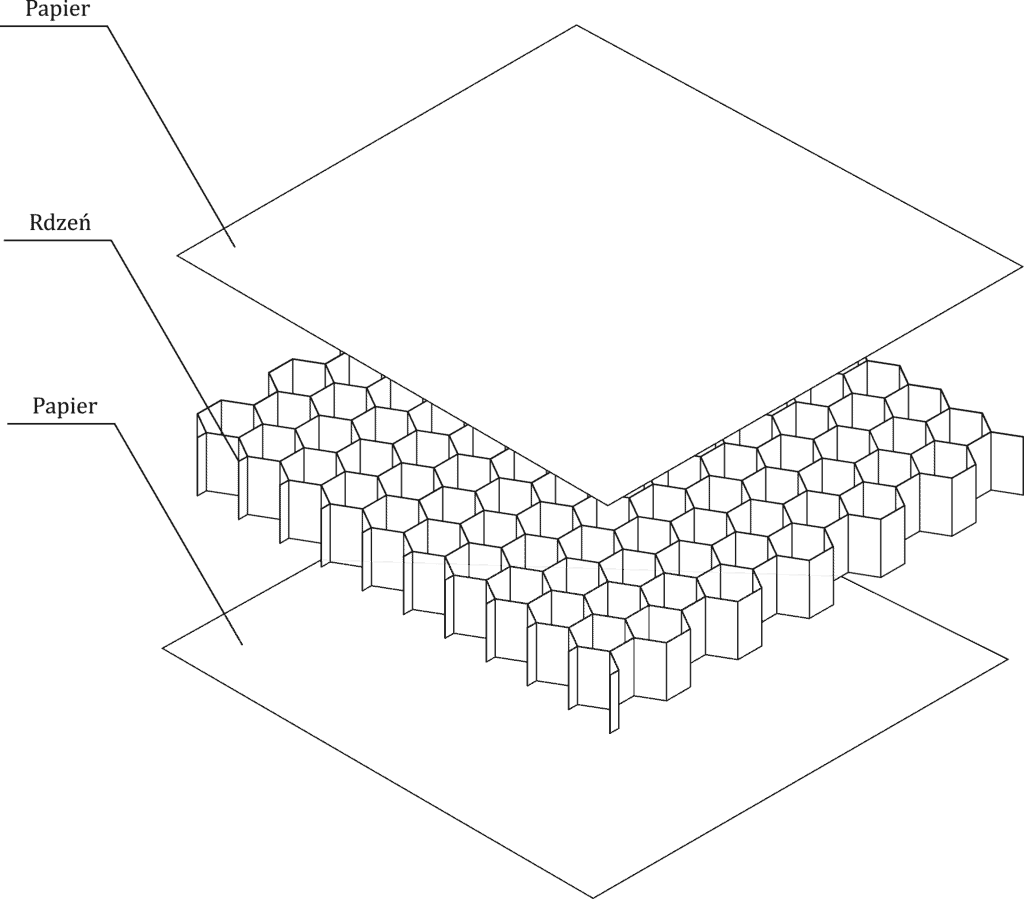

When looking for new solutions, it often turns out that the simplest ones are the most effective ones and that they deserve a phased expansion. This statement very well presents the specific nature of the material which is a honeycomb paper board, colloquially also referred to as a honeycomb board. It has a very simple structure shown in the picture below (1).

(1) Construction of a honeycomb board.

In short, these are two outer papers with a hexagonal core in the middle. A structure composed of such solutions has a huge multitude of combinations of components, such as adhesives with different viscosities and elasticity, papers based on a wide range of basis weight, as well as the height of the core and the size of its cells. This gives a very large spectrum of possibilities in choosing the right combination for a specific demand. In addition, special attention should be paid to the properties of the material after crushing – it becomes soft, resilient and susceptible to bending, resembling a bubble wrap with its structure.

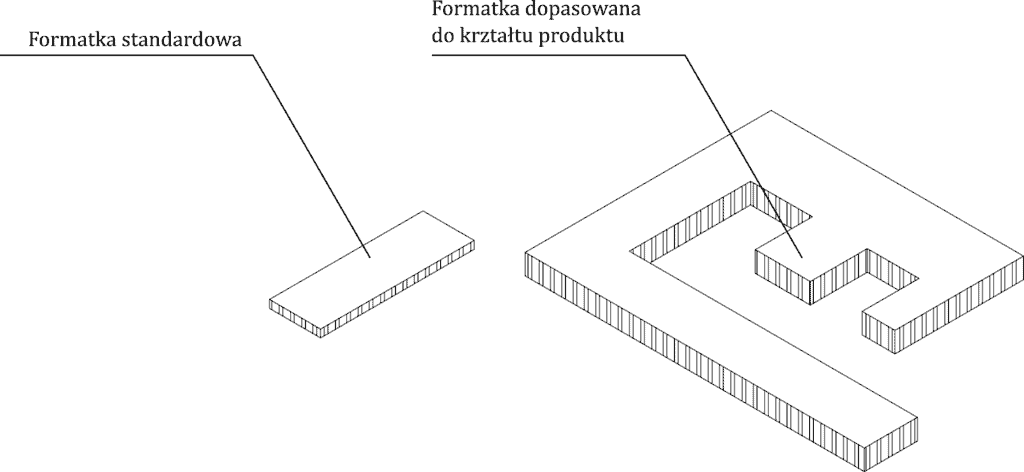

Another very important element is the structure of the board, which has a high resistance to vertical pressure and much lower in the case of exposed side edges, which placed in good position are ideal, for example, as a product shock absorber. An important role is also played by the machining of the material, which begins with a very simple form of filler in the packaging with a wide range of height and width, and ending with much more complex and closely matched to the product forms (2), cut according to a specific pattern using a plotter.

(2) Types of honeycomb fillers.

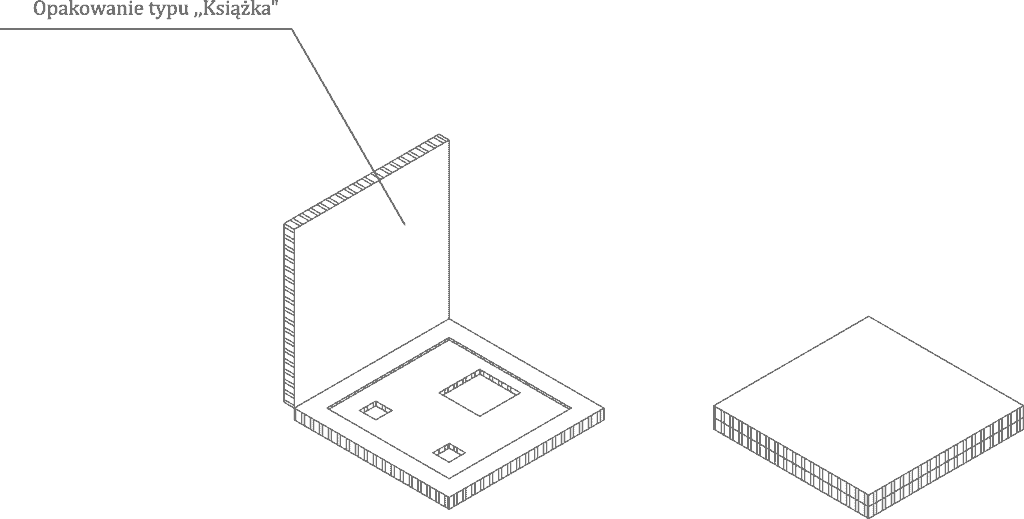

The honeycombed paper plate will also work as an independent, embossed pack in the form of a “book” (3) or a standard box. The said products are only a fraction of the whole, because the discussed board have a much wider application, including in production of:

- paper pallets,

- advertising displays,

- spacers and product stabilizers,

- they also prove to be a building material for the construction of exhibition stands and many others.

(3) Honeycomb book-type packaging.

How to choose the right board for your needs?

When choosing the right parameters for a honeycomb paperboard, you should mainly focus on its final purpose. It is therefore important that each component used in the production process accurately reflects the nature of the product. The discussed material, i.e. a honeycomb plate, has three main components that, with the right combination, will create a material with various properties. These are:

- top/bottom paper,

- bonding glue.

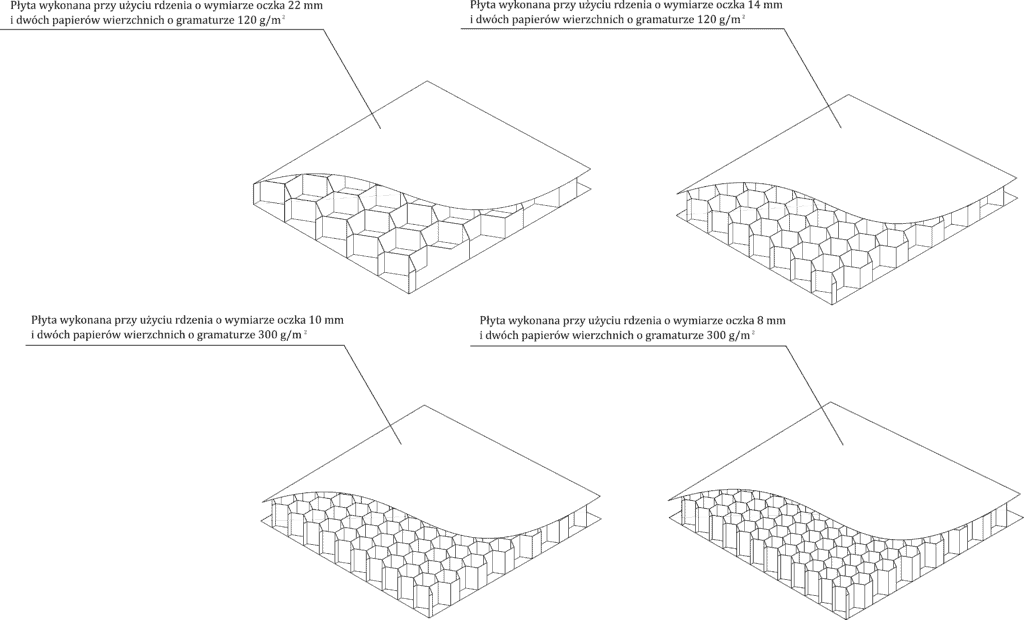

Imagining the whole very briefly, we could identify the four most common types of honeycomb panels. (4)

- Cell size 22 mm / Paper 120 g / m2 – this board has the least resistance to compression, but its main advantage is its low weight and reduced production cost. The large size of the cell will allow for cushioning properties. Perfect for protecting lighter elements or filling empty packaging spaces.

- Cell size 14 mm / Paper 120 g / m2 – these are definitely the most popular parameters. It is an ideal price-quality ratio, it works great as a filler for empty spaces, e.g. when packing furniture items.

- Cell size 10 mm / Paper 300 g / m2 – a given board due to the high basis weight of the top/bottom paper and the use of a small mesh size has a significantly increased stiffness and compressive strength. Thanks to this, it will be perfect for the production of paper pallets or more complex projects.

- Cell size 8 mm / Paper 300 g / m2 – is a paper plate with very high compressive strength and stiffness. Used most often in the production of pallets, construction of exhibition stands or advertising stands.

(4) Basic types of paper honeycomb board.

A very important issue in choosing the right board is to adjust the correct height. It usually varies between 8 mm and 104 mm. It is also worth noting that as the height increases, not only the weight, but also the stiffness of the material increases.

The specifications listed above are only examples based on commonly used materials and do not reflect the multitude of configurations that can be obtained when combining components with different specifications. When choosing a product, first of all remember that the most important thing is to adjust all parameters so that they fully meet our needs and fulfill their function in 100%.

P.S. Do you have more questions? Are not sure which boards will be suitable for your needs? Our specialists can easily help you choose the right specification! We kindly invite you to contact us.

(Author: Aleksander Rożek, Product Designer)